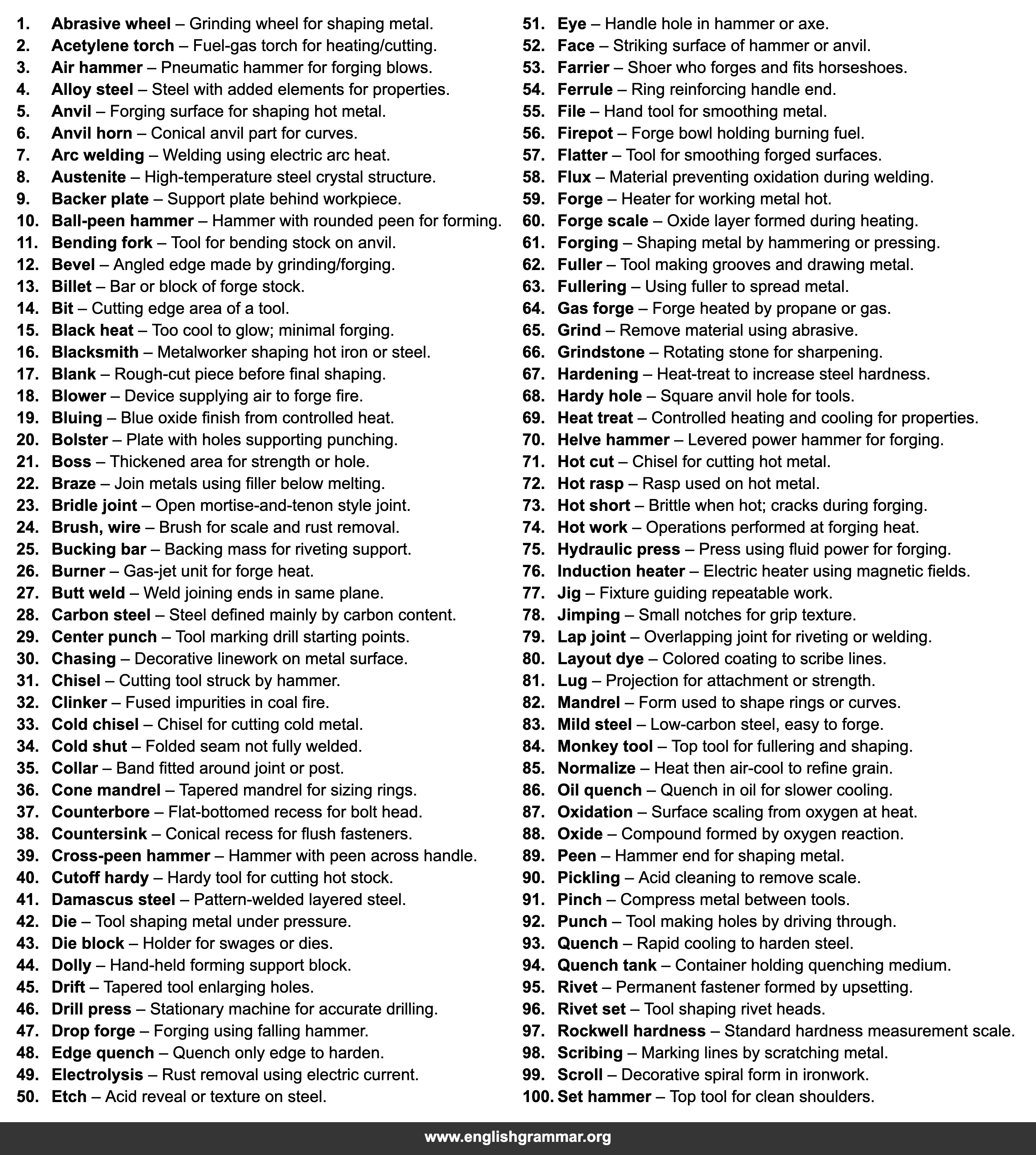

| No. | Term | Definition |

|---|---|---|

| 1. | Abrasive wheel | Grinding wheel for shaping metal. |

| 2. | Acetylene torch | Fuel-gas torch for heating/cutting. |

| 3. | Air hammer | Pneumatic hammer for forging blows. |

| 4. | Alloy steel | Steel with added elements for properties. |

| 5. | Anvil | Forging surface for shaping hot metal. |

| 6. | Anvil horn | Conical anvil part for curves. |

| 7. | Arc welding | Welding using electric arc heat. |

| 8. | Austenite | High-temperature steel crystal structure. |

| 9. | Backer plate | Support plate behind workpiece. |

| 10. | Ball-peen hammer | Hammer with rounded peen for forming. |

| 11. | Bending fork | Tool for bending stock on anvil. |

| 12. | Bevel | Angled edge made by grinding/forging. |

| 13. | Billet | Bar or block of forge stock. |

| 14. | Bit | Cutting edge area of a tool. |

| 15. | Black heat | Too cool to glow; minimal forging. |

| 16. | Blacksmith | Metalworker shaping hot iron or steel. |

| 17. | Blank | Rough-cut piece before final shaping. |

| 18. | Blower | Device supplying air to forge fire. |

| 19. | Bluing | Blue oxide finish from controlled heat. |

| 20. | Bolster | Plate with holes supporting punching. |

| 21. | Boss | Thickened area for strength or hole. |

| 22. | Braze | Join metals using filler below melting. |

| 23. | Bridle joint | Open mortise-and-tenon style joint. |

| 24. | Brush, wire | Brush for scale and rust removal. |

| 25. | Bucking bar | Backing mass for riveting support. |

| 26. | Burner | Gas-jet unit for forge heat. |

| 27. | Butt weld | Weld joining ends in same plane. |

| 28. | Carbon steel | Steel defined mainly by carbon content. |

| 29. | Center punch | Tool marking drill starting points. |

| 30. | Chasing | Decorative linework on metal surface. |

| 31. | Chisel | Cutting tool struck by hammer. |

| 32. | Clinker | Fused impurities in coal fire. |

| 33. | Cold chisel | Chisel for cutting cold metal. |

| 34. | Cold shut | Folded seam not fully welded. |

| 35. | Collar | Band fitted around joint or post. |

| 36. | Cone mandrel | Tapered mandrel for sizing rings. |

| 37. | Counterbore | Flat-bottomed recess for bolt head. |

| 38. | Countersink | Conical recess for flush fasteners. |

| 39. | Cross-peen hammer | Hammer with peen across handle. |

| 40. | Cutoff hardy | Hardy tool for cutting hot stock. |

| 41. | Damascus steel | Pattern-welded layered steel. |

| 42. | Die | Tool shaping metal under pressure. |

| 43. | Die block | Holder for swages or dies. |

| 44. | Dolly | Hand-held forming support block. |

| 45. | Drift | Tapered tool enlarging holes. |

| 46. | Drill press | Stationary machine for accurate drilling. |

| 47. | Drop forge | Forging using falling hammer. |

| 48. | Edge quench | Quench only edge to harden. |

| 49. | Electrolysis | Rust removal using electric current. |

| 50. | Etch | Acid reveal or texture on steel. |

| 51. | Eye | Handle hole in hammer or axe. |

| 52. | Face | Striking surface of hammer or anvil. |

| 53. | Farrier | Shoer who forges and fits horseshoes. |

| 54. | Ferrule | Ring reinforcing handle end. |

| 55. | File | Hand tool for smoothing metal. |

| 56. | Firepot | Forge bowl holding burning fuel. |

| 57. | Flatter | Tool for smoothing forged surfaces. |

| 58. | Flux | Material preventing oxidation during welding. |

| 59. | Forge | Heater for working metal hot. |

| 60. | Forge scale | Oxide layer formed during heating. |

| 61. | Forging | Shaping metal by hammering or pressing. |

| 62. | Fuller | Tool making grooves and drawing metal. |

| 63. | Fullering | Using fuller to spread metal. |

| 64. | Gas forge | Forge heated by propane or gas. |

| 65. | Grind | Remove material using abrasive. |

| 66. | Grindstone | Rotating stone for sharpening. |

| 67. | Hardening | Heat-treat to increase steel hardness. |

| 68. | Hardy hole | Square anvil hole for tools. |

| 69. | Heat treat | Controlled heating and cooling for properties. |

| 70. | Helve hammer | Levered power hammer for forging. |

| 71. | Hot cut | Chisel for cutting hot metal. |

| 72. | Hot rasp | Rasp used on hot metal. |

| 73. | Hot short | Brittle when hot; cracks during forging. |

| 74. | Hot work | Operations performed at forging heat. |

| 75. | Hydraulic press | Press using fluid power for forging. |

| 76. | Induction heater | Electric heater using magnetic fields. |

| 77. | Jig | Fixture guiding repeatable work. |

| 78. | Jimping | Small notches for grip texture. |

| 79. | Lap joint | Overlapping joint for riveting or welding. |

| 80. | Layout dye | Colored coating to scribe lines. |

| 81. | Lug | Projection for attachment or strength. |

| 82. | Mandrel | Form used to shape rings or curves. |

| 83. | Mild steel | Low-carbon steel, easy to forge. |

| 84. | Monkey tool | Top tool for fullering and shaping. |

| 85. | Normalize | Heat then air-cool to refine grain. |

| 86. | Oil quench | Quench in oil for slower cooling. |

| 87. | Oxidation | Surface scaling from oxygen at heat. |

| 88. | Oxide | Compound formed by oxygen reaction. |

| 89. | Peen | Hammer end for shaping metal. |

| 90. | Pickling | Acid cleaning to remove scale. |

| 91. | Pinch | Compress metal between tools. |

| 92. | Punch | Tool making holes by driving through. |

| 93. | Quench | Rapid cooling to harden steel. |

| 94. | Quench tank | Container holding quenching medium. |

| 95. | Rivet | Permanent fastener formed by upsetting. |

| 96. | Rivet set | Tool shaping rivet heads. |

| 97. | Rockwell hardness | Standard hardness measurement scale. |

| 98. | Scribing | Marking lines by scratching metal. |

| 99. | Scroll | Decorative spiral form in ironwork. |

| 100. | Set hammer | Top tool for clean shoulders. |